Easie develops nationwide cold chain e-commerce system for açaí manufacturer

The importance of cold chain logistics has been made apparent by the recent announcements of COVID-19 vaccines by Pfizer, Moderna and AstraZeneca. Each vaccine requires a cold supply chain to keep the vaccine from degrading and dramatically losing efficacy during transit. Each product formulation has its own unique logistics requirements and may require a refrigerated or frozen supply chain solution.

An unbroken cold chain starting from production and storage through distribution and end-user delivery requires specialized logistics, equipment and expertise. Cold chain logistics can preserve, maintain or extend product shelf life and is used heavily by food, materials, chemicals, biotech and many other industries.

Açaí is a frozen sorbet product generally imported from Brazil that must be shipped frozen (32F) for the entirety of the supply chain to avoid melting during transit.

Easie was contracted by San Diego-based açaí manufacturer Açaí Roots in Q1 2019 to help expand sales by establishing an automated cold chain e-commerce system for wholesale and personal açaí orders to the entirety of the United States (including Alaska and Hawaii) without melting.

Easie had deep historical experience with complex domestic and international logistics and business development prior to starting this project.

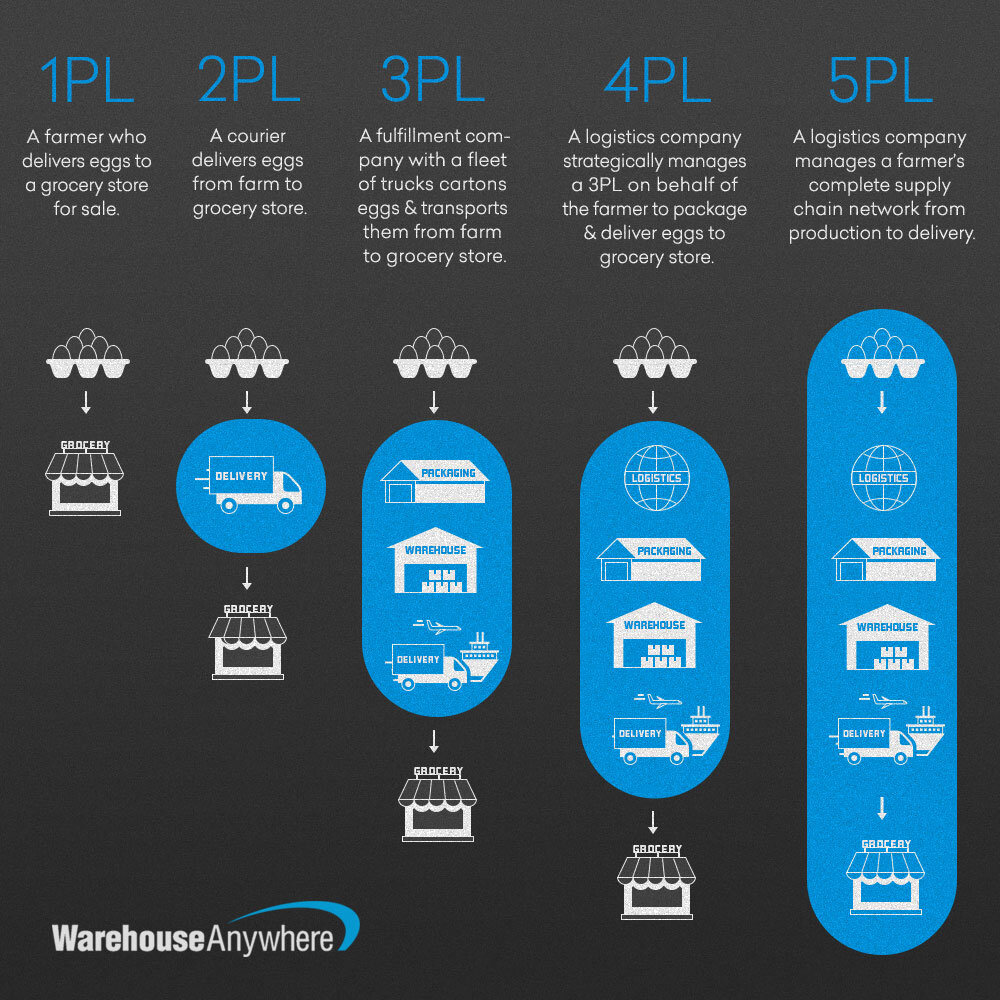

Easie developed and launched a nationwide, cold chain logistics e-commerce system as a fourth-party logistics firm (“4PL”) for Açaí Roots that successfully launched in Q1 2020 and is still in use today. This article describes our methodology, business development processes and notable findings from completing this project.

In addition to logistics and e-commerce development, the company also required guidance with marketing, product analysis and general promotion of the new e-commerce program to launch with maximum impact.

This required additional analysis outside of logistics-specific activities such as product research, sales forecasting and business profitability analysis.

Here is what Marco Rega, CEO of Açaí Roots said about his experience with Easie:

“Easie developed an excellent e-commerce program for my company and I highly recommend them to anyone that is looking into growing their e-commerce business. They have an outstanding knowledge and are always willing to listen and share their ideas to maximize our sales. We are very satisfied by choosing to work with them!”

- Marco Rega, Co-Founder & CEO, Açaí Roots

Methodology

The project kicked off with an analysis of key features for the business system so we could identify the associated technologies that could meet those requirements. We generated a features matrix outlining discrete requirements for the high-level functionality.

The overall methodology consisted of evaluating candidate technology profiles, creating unique business process architecture and then doing a lot of research on options for third-party logistics companies (“3PLs”) around the United States using scoring criteria against identified metrics.

Figure 1.1 - Logistics relationship diagrams (4)

One of the primary goals of the feasibility study was picking the physical locations of distribution centers and finding a 3PL to actually handle storing and fulfilling orders while having the needed distribution center locations around the United States. The 3PL also needed to be able to integrate programmatically with the system via API.

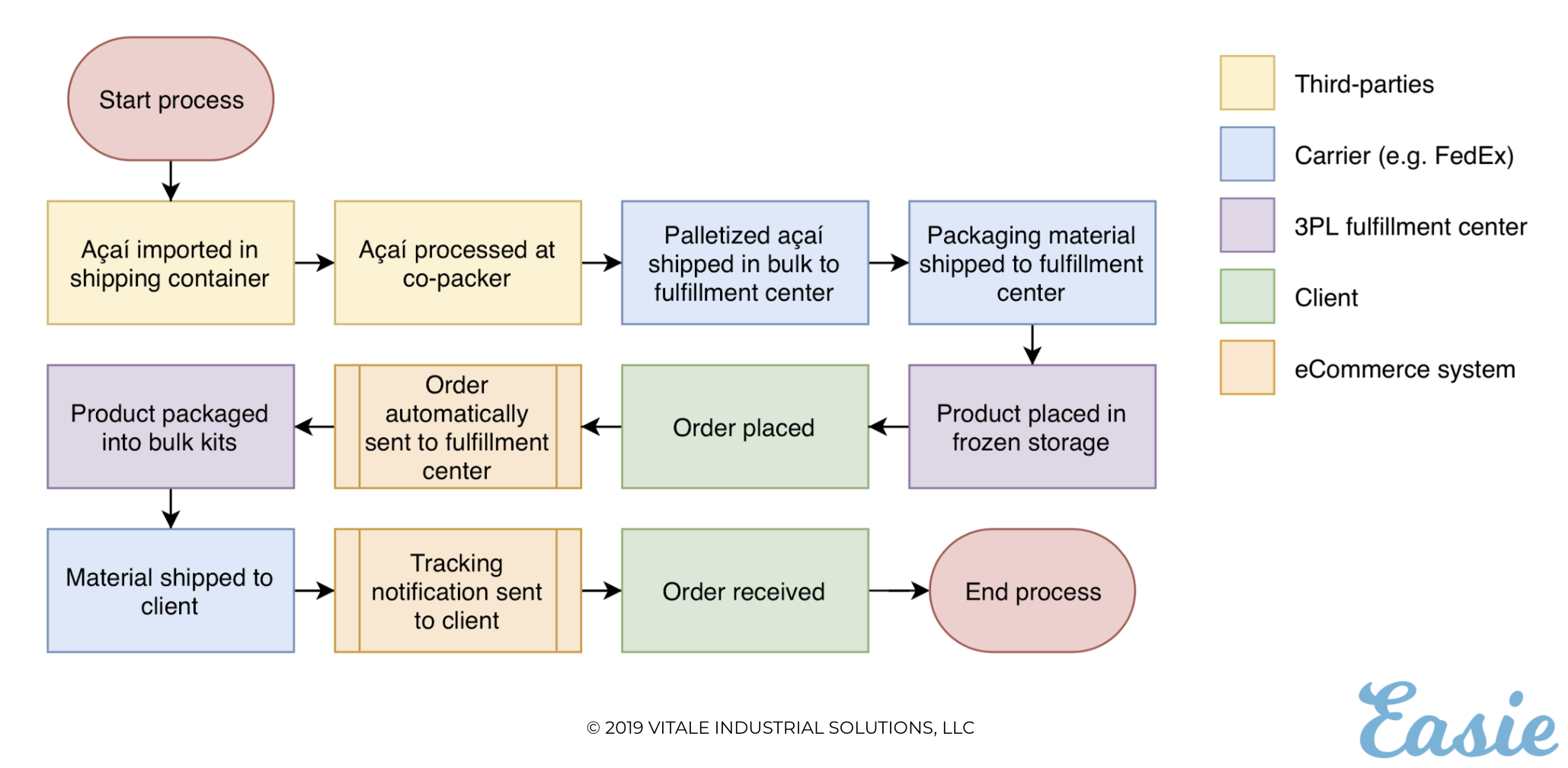

Here is the high-level business process generated from project kickoff activities:

Figure 1.2 - Draft e-commerce process flow after feasibility study

E-commerce site & business feasibility study

We selected Shopify as the e-commerce platform primarily because of the optimization for e-commerce and broader integration capabilities for some of the other elements that were needed in the functionality of the system (integration with 3PL via API, custom frontend functionality, advanced freight modeling, etc.).

Despite semi-complex requirements, the starting plan on Shopify ($29/month) was sufficient and a higher Shopify plan was not required for this project (although a Shopify theme was used that required a one-time fee).

Besides the website platform, we also considered what would be the optimal product line to offer for e-commerce given the historical reorder rate. We evaluated historical data using Tableau and determined the average days between orders to see what a B2C customer might reasonably order in a given time period.

Based on historical reordering analysis, existing products created and inventory on-hand, we determined the initial product line that would be offered in collaboration with Açaí Roots leadership using existing products in their product line.

Figure 1.3 - Example average days between orders using Tableau

Since each individual order would be shipping less-than-truckload (“LTL”), dry ice was required (as opposed to gel packs) in each individual packaging for movement of açaí with about 33% of gross weight (weight of styrofoam packaging, dry ice and product) being dry ice for a given shipment. Further, through packaging testing, we found that packaging efficiency (net weight divided by gross weight) fluctuated around 42% to 50% per shipment.

Transit itself would occur in a non-temperature controlled transportation unit for two-day freight, underscoring the importance of standardized procedures for packaging products with the 3PL. Because of the high cost, fully refrigerated or frozen transportation units are mostly for full-truckload (“FTL”) shipments where individual packagings are not packed with temperature-controlling materials.

Cold chain freight also requires specialized dangerous goods labeling, markings on packagings and a customer-first written return policy for instances of process failure.

After establishing the initial business processes and identifying candidate 3PLs specialized in cold chain logistics, we also considered a major question: where are the optimal places to locate distribution centers around the country?

Figure 1.4 - Summer temperatures graphic from MIT study (1)

During our research, we found a 2015 report by MIT researchers titled “E-commerce cold chain fulfillment” (1) and contacted the authors of the study. One of the authors replied and shared insights over a conference call from his research that profoundly helped inform the study. Seeking expert judgement from existing research moved the feasibility study forward rapidly.

Here was a notable excerpt from the MIT report:

“E-Commerce is a growing channel and companies can leverage options in the four segments of consumer delivery. While there is no single solution that will optimize the delivery of all perishable goods, companies can look to a holistic view utilizing a scorecard to design the supply chain that best fits the business needs.

Network optimization and retail partnered returns offer opportunities to lower cost, increase speed, and boost quality; but these options are not achievable without investment.”

- E-commerce cold chain fulfillment report; MIT (1)

This research validated that placement of distribution centers was critical and could minimize the transit time throughout the United States while lowering the risk of product loss from melting, excess inventory exposure or business process defects.

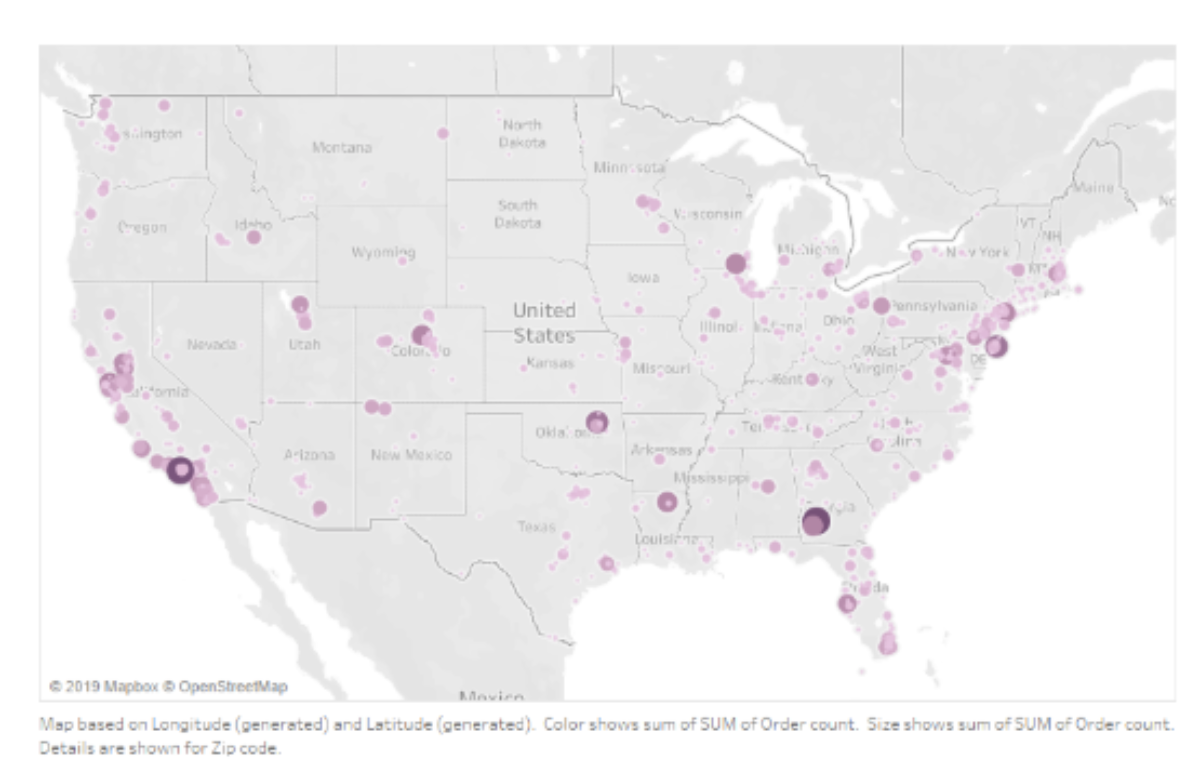

Besides the objective physical optimization of land area, we also had to consider what was the right placement of distribution centers based on forecasted demand?

Figure 1.5 - Forecasted açaí demand analysis using Tableau

The end result of this research was an identified 3PL vendor and an optimized distribution center breakdown with approximately 96% of the country covered by two-day freight. The following map shows an example breakdown and transit time heat map for a three-distribution center breakdown in the United States:

Figure 1.6 - Example transit time from three FedEx distribution centers (3)

There were instances where some customers were in deeply remote geographic locations or in non-mainland areas of the United States (e.g. Alaska or Hawaii). To address this, Easie developed a custom financial model that determined what the shipping price should be automatically using the zip code of the order. This required analysis using data provided by FedEx as well as technical configuration of Shopify plugins to execute the conditional freight cost calculation requirements against the model data.

The custom freight cost calculation model and 3PL relationship with the selected vendor were finalized and we integrated the Shopify website with the 3PL proprietary system using the Shopify API.

After identifying where the distribution centers would be and integrating with the 3PL, Easie then rigorously tested the system by sending açaí to many different locations in the mainland United States as well as to consignees in Alaska and Hawaii.

The root cause of failures identified during testing were found to be associated with the 3PL having a “learning curve” for the specific system (defects during a team getting used to a new system are common) which were resolved with further iterations.

We continued to iteratively improve during testing and QA until the success rate reached 100% of shipments received intact, frozen and without product defects. This rate was deemed sufficient for launch against FedEx’s reported average cold chain failure rate of 98% and pre-launch activities were started.

Results & conclusion

Easie mixed data from current research trends and an isolated order history from the past decade to figure out where to strategically locate distribute centers and where to focus on pre-launch marketing activities to ensure maximum reach with inventory on-hand. a 3PL was identified and Easie acted as a 4PL during the process of establishing a customized cold chain logistics system on behalf of Açaí Roots.

Social media activities and a pre-launch marketing campaign were conducted prior to launch to spread awareness and excitement for the new offering. The system successfully launched in Q1 of 2020 as expected with positive reception, marking expanded business growth for Açaí Roots.

The system continues to see orders today using the framework established by Easie during this project.

Easie can help develop your unique logistics program

Schedule a free 15-minute consultation.

Citations

https://www.warehouseanywhere.com/resources/3pl-vs-4pl-logistics-definition-and-comparison/

This article was edited by Whitney Brittingham.

A special thanks to Easie specialist Jack Marchese for being a critical member of this project.