Computer vision in complex manufacturing: detecting defects in real-time with Amazon Lookout for Vision and Rekognition labels

The use of computer vision and machine learning in manufacturing is revolutionizing the industry, offering many benefits for businesses looking to improve their processes, ensure quality and increase efficiency. This article explores a novel technology approach using a combination of Amazon Lookout for Vision and Amazon Rekognition Custom Labels to detect defects in complex manufacturing systems.

Amazon Lookout for Vision is a machine learning service that uses computer vision to identify defects in products and equipment, while Amazon Rekognition Custom Labels is a computer vision service that can be trained to recognize specific objects, scenes and activities in images and videos.

By using high-performance cameras in production lines, manufacturers can capture images and video of components as they are produced in real time.

These images can then be analyzed by computer vision algorithms to detect any defects or abnormalities in the manufacturing process. Here is a simplifed workflow for computer vision process using Amazon Lookout and Amazon Rekognition:

Figure 1.1: Workflow for computer vision process

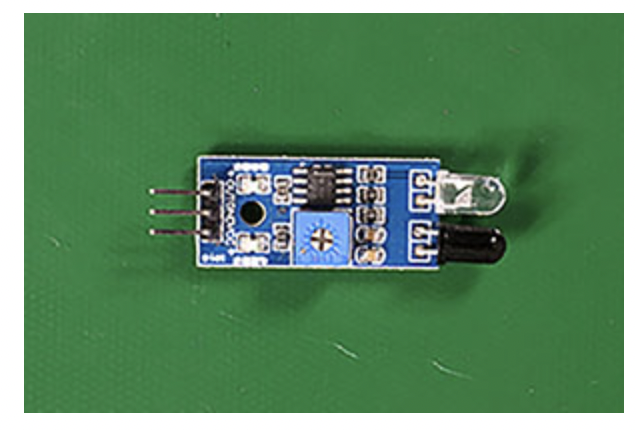

The benefits of using computer vision in manufacturing affect all manufacturing sectors. For example, in electronics manufacturing, computer vision can be used to detect faulty components, such as bent pins or soldering defects, which can be difficult to spot with the naked eye.

Figure 1.2: Example of defective component (bent pin)

Figure 1.3: Example of non-defective component

Computer vision helps manufacturers identify and correct production issues in real-time, reducing waste and increasing efficiency

By using Amazon Lookout for Vision and Amazon Rekognition Custom Labels, plant operators can gain a granular view of the types of defects occurring during production and take corrective actions in real-time. This can help reduce scrap and rework, as well as improve product quality and reduce costs.

Here are some other examples of how computer vision can be applied to complex manufacturing processes:

Precision manufacturing: In precision manufacturing, even a small error can lead to significant losses. By using machine learning and computer vision, manufacturers can detect defects in real-time and prevent defective products from reaching the market. For example, a company that produces microchips could use computer vision to detect minute defects that might be missed by the human eye, ensuring that only high-quality chips are shipped to customers.

Biotech manufacturing: Biotech manufacturing involves the production of complex biological molecules such as proteins and antibodies. These molecules are highly sensitive and can be easily damaged during the manufacturing process, leading to defects. By using computer vision and machine learning, biotech manufacturers can identify defects in real-time and take corrective action before products are shipped. For example, a biotech company that produces antibodies could use computer vision to detect aggregation, which occurs when multiple antibodies clump together, leading to reduced potency.

Automotive manufacturing: In automotive manufacturing, even a small defect can lead to safety issues and costly recalls. By using computer vision and machine learning, manufacturers can detect defects in real-time and prevent unsafe products from reaching the market. For example, a car manufacturer could use computer vision to detect defects in the welding process, which could lead to weakened structural integrity and safety issues.

Aerospace manufacturing: In aerospace manufacturing, defects can be catastrophic and lead to the loss of life. By using computer vision and machine learning, manufacturers can identify defects early in the production process and prevent unsafe products from being used. For example, an aerospace manufacturer could use computer vision to detect defects in the turbine blades used in jet engines, which could cause catastrophic engine failure.

Consumer electronics manufacturing: In consumer electronics manufacturing, defects can lead to costly recalls and damage to the brand's reputation. By using computer vision and machine learning, manufacturers can detect defects in real-time and prevent faulty products from reaching consumers. For example, a smartphone manufacturer could use computer vision to detect defects in the screen manufacturing process, which could lead to a lower-quality display or a shorter lifespan.

Industrial safety: In industrial settings, safety is of paramount importance to protect workers from accidents and injuries. By using computer vision and machine learning, manufacturers can monitor employees to ensure that they are following safety protocols and wearing the required personal protective equipment (PPE). For example, a manufacturing plant could use computer vision to detect whether workers are wearing hard hats and safety glasses, and alert the supervisor if someone is not in compliance. Additionally, computer vision could also be used to detect unsafe behaviors, such as workers standing too close to dangerous machinery or improper use of equipment. By detecting and correcting these behaviors in real-time, manufacturers can reduce the risk of accidents and injuries in the workplace, while improving overall safety for their employees.

At Easie, we have experience working with AWS Rekognition and image/video streams to produce business-specific conclusions in the past. Our team believes that this technology can be of great value to businesses in various types of manufacturing, and we look forward to exploring further how we can work together to leverage this technology.

Figure 1.4: Demo of computer vision technology Easie built that recognizes PPE in a video stream

In conclusion, computer vision and machine learning are changing the manufacturing industry, offering many benefits for businesses looking to improve their processes and increase efficiency. With Amazon Lookout for Vision and Amazon Rekognition Custom Labels, manufacturers can detect defects in high-precision manufacturing and take corrective actions in real-time, helping to reduce waste, improve quality, and increase efficiency.

Get in touch with our team to learn more about computer vision services.